Description

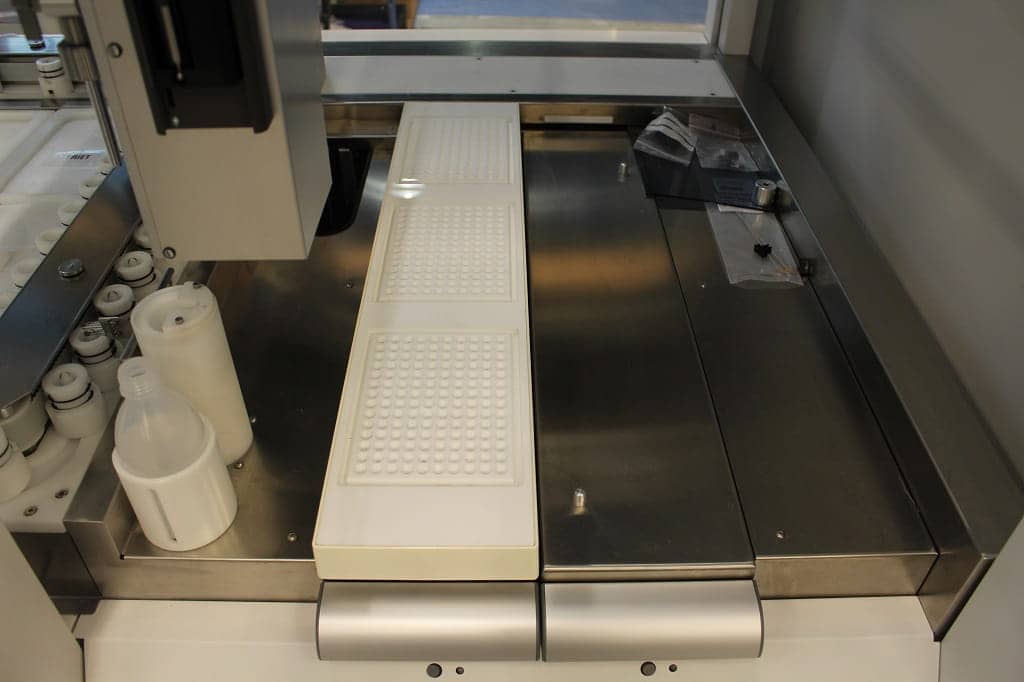

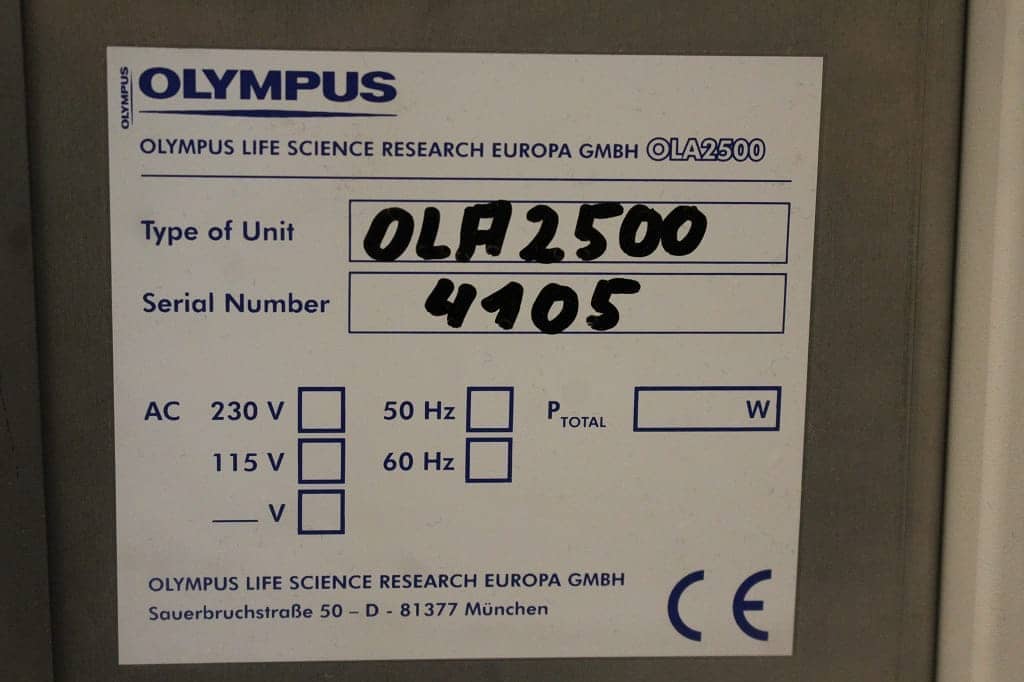

Save precious time and gain efficiency in the lab with the OLA2500 Lab Automation System (LAS), the high-throughput aliquotting solution with pre- and post-analytical sample-processing capabilities. The Olympus OLA2500 LAS is an advanced modular automation system designed for medium- to high-volume laboratories. As a front-end sample-processor the OLA2500 LAS automates sample aliquotting – saving time, labor, and eliminating sample handling errors. The system also selectively decaps and sorts tubes to any analyzer sample rack.

The Olympus OLA2500 LAS is a Olympus Lab Automation solution to increase productivity and efficiency in medium- to high-volume laboratories. It automates labor-intensive tasks such as sample identification, decapping, aliquotting, out sorting, and archive preparation of sample tubes.

Typical aliquotting throughput of up to 650 total tubes per hour and sorting throughput of up to 800 tubes per hour to reduce your sample preparation for better test turn-around time

Minimize your staff’s biohazard exposure, reduce errors, and reduce repetitive motion injuries associated with manual sample-processing

User-defined applications for aliquotting priority, sorting, decapping, and archiving.

Identifies sample tube size, cap type and color, and sample volume using an on board digital image analysis system

Processes most primary tubes (including conventional, BD Hemoguard or screw top closures in parallel, foil top closures with optional decapping unit)

Builds personality racks for Olympus, Hitachi, Beckman-Coulter and others

Automatically generate secondary tubes with user defined barcode labels

No carryover with disposable, conductive aliquot tips

Clot detection to ensure valid sample distribution

Prioritized aliquotting when there is insufficient amount of sample in the primary tube

Load up to as many as 300 samples in the input area

Sort to any number of user defined sorting targets with up to 1,080 tube capacity at the destination area

Holds bulk on-board consumable inventory

Sort and speed primary and/or secondary samples to workstations in specific analyzer racks

Access samples without interrupting the instrument with electronically controlled drawer bays

Sorts primary and secondary sample tubes at high speeds to meet peak load demands

Archive samples in parallel with sorting or separately in batch

User defined sorting areas that accommodates any analyzer sample rack

Reduces the number of “problem tubes” at the analytical workstations by sorting out the tubes with bar code label, test order and decapping problems

Decap screw cap and conventional rubber closures in parallel with a standard decapper; an optional decapper handles foil top closures

Specifications

| Weight | 0,0 kg |

|---|